Roll Forming Frame for the Energy Industry

At Johnson Brothers Roll Forming Co., we provide high quality metal forming services that serve the needs of customers across a broad range of industries.

Since 1948, we’ve been providing custom-made, roll-formed metal parts that deliver robust quality and value.

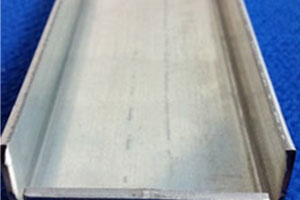

We were recently contracted by a Washington-based solar technologies customer seeking a manufacturer for their unique solar panel product. This system would use repositionable solar panels designed to automatically seek out the best direction angle for sunlight. Our role in this project provided the customer the solar module support framing necessary for these panels.

Our fabrication work consisted of roll forming frame channels and pieces according to customer specifications. The material used was mild steel, processed under tolerances of ±.01 mm. After forming, each frame piece was treated with a G90 zinc coating for corrosion protection. Each solar module frame measured 935.8 mm by 136.7 mm, with a sheet metal thickness of 1.59 mm.

The customer contracted multiple 45,000 lb. orders that we processed on 2 to 4 week lead times. Completed orders were delivered direct to the customer’s facilities in Kennewick, WA. Thanks to our assistance, this customer found a complete manufacturing solution. Feel free to contact us directly to learn more about our services and other capabilities.

Project Specifications

- Project Name & Description

Solar Panel / Module Frames

- Capabilities Applied / Processes

Roll Forming

- Overall Part Dimensions

Length: 935.8 mm

Width: 136.7 mm

Thickness: 1.59 mm

- Tightest Tolerances

±.01 mm

- Material Used

Mild Steel

- Material Finish

Zinc Coated to G90

- Industry for Use

Energy

- Volume

45,000 lbs / Order

- Delivery / Turnaround Time

2-4 Weeks After Tooling

- Delivery Location

Kennewick, Washington

- Standards Met

Customer Specification , 2D CAD Model

JOHNSON BROS. ROLL FORMING CO.

Johnson Bros. Roll Forming Co. provides high quality custom roll forming services and ISO 9001 compliant press fabrication, utilizing state of the art inline press punching equipment.