Punched Wall Form Liners for the Construction Industry

Through a persistent dedication to precision and accuracy, we can provide rolled metal pieces and channels that answer the needs of your projects and products exactly.

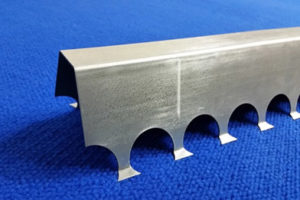

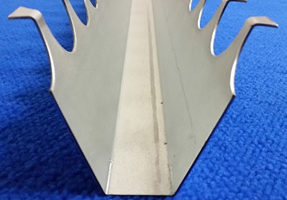

We recently assisted a customer through the fabrication of wall form liners, an important tool in the prefabricated concrete construction industry. These liners allow prefabricated walls to feature embossed designs, protective ribbing, or sound absorbing characteristics.

We manufactured these wall form liners using our in-house punching and forming process. 16 Gage Cold Rolled steel was punch pressed, formed, and cut to various lengths ranging from 83″ to 168″, as determined by customer specification. Each sheet was also galvanized for rust protection.

We completed and delivered this project on an efficient 6-week lead time, with 50,000 ft. (80,000 lbs.) of form liners manufactured. Our participation allowed this customer to have a crucial construction product delivered promptly and built to specification.

For more information about our services, feel free to contact us directly.

Project Specifications

- Project Name & Description

Wall Form Liners

- Lightweight Precast Wall Panels

- Capabilities Applied / Processes

Punch Press, Formed, Cut to Length

- Overall Part Dimensions

Cut to Various Lengths: 83” – 168”

- Material Used

Cold Rolled Steel

- 16 Gage

- Material Finish

Galvanized

- Industry for Use

Construction

- Volume

50,000 ft / 80,000 lbs.

- Delivery / Turnaround Time

6 Weeks

- Standards Met

Customer Specification

JOHNSON BROS. ROLL FORMING CO.

Johnson Bros. Roll Forming Co. provides high quality custom roll forming services and ISO 9001 compliant press fabrication, utilizing state of the art inline press punching equipment.